The trial phase will span up to 24 months and involves the deployment of 16 advanced hydrogen-powered vehicles with varying configurations and payload capacities.

Tata Motors launched the first-ever trials of hydrogen-powered heavy-duty trucks. This trial, which marks a significant step towards sustainable long-distance cargo transportation, was flagged off by Nitin Gadkari, Union Minister of Road Transport & Highways, and Pralhad Joshi, Union Minister of New and Renewable Energy. The ceremony also saw the participation of Girish Wagh, Executive Director, Tata Motors, among other delegates from the Government of India and the two companies.

Tata Motors awarded the tender for this trial, which is funded by the Ministry of New and Renewable Energy under the National Green Hydrogen Mission. It marks a significant step forward in assessing the real-world commercial viability of using hydrogen-powered vehicles for long-distance haulage as well as setting-up the requisite enabling infrastructure for their seamless operation.

The trial phase will span up to 24 months and involves the deployment of 16 advanced hydrogen-powered vehicles with varying configurations and payload capacities. These trucks, equipped with new age Hydrogen Internal Combustion Engines (H2-ICE) and Fuel Cell (H2-FCEV) technologies, will be tested on India’s most prominent freight routes, including those around Mumbai, Pune, Delhi-NCR, Surat, Vadodara, Jamshedpur and Kalinganagar.

Nitin Gadkari, Union Minister of Road Transport and Highways, Government of India, said, “Hydrogen is the fuel of the future with immense potential to transform India’s transportation sector by reducing emissions and enhancing energy self-reliance. Such Initiatives will accelerate the transition to sustainable mobility in heavy-duty trucking and move us closer to an efficient, low-carbon future.

”Pralhad Joshi, Union Minister of New and Renewable Energy, Government of India said, “Hydrogen is an important fuel for India’s transition to a sustainable and zero-carbon future. The beginning of this trial is a significant step forward in showcasing the potential of green hydrogen in decarbonizing India’s transportation sector. This initiative, part of the National Green Hydrogen Mission, reflects our commitment to driving innovation and achieving India’s energy independence while contributing to global climate goals.”

The flagged-off vehicles exemplify Tata Motors’ comprehensive approach to hydrogen mobility, displaying H2ICE and Hydrogen Fuel Cell Electric Vehicle (FCEV) technologies. This includes two Tata Prima H.55S prime movers—one powered by H2ICE and the other by FCEV, alongside the Tata Prima H.28, an advanced H2ICE truck. With an operational range of 300-500 km, these vehicles are engineered for sustainable, cost-efficient, and high-performance transportation. Featuring the premium Prima cabin and advanced driver-assist safety features, they enhance driver comfort, reduce fatigue, and improve productivity while setting new benchmarks for safety in trucking.

Tata Motors is at the forefront of developing innovative mobility solutions powered by alternative fuel technologies such as battery electric, CNG, LNG, hydrogen internal combustion, and hydrogen fuel cell. The company offers a robust portfolio of alternate-fuel powered commercial vehicles across various segments, including small commercial vehicles, trucks, buses and vans. The company had won a tender of 15 Hydrogen FCEV buses, which are successfully deployed on Indian roads.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

This implementation reduced carbon emissions of the JSW plant by 1,800 tons, reaffirming the brand’s promise towards innovation by adopting holistic sustainable practices.

JSW MG Motor India became the first Original Equipment Manufacturer (OEM) to implement a Green Pretreatment line in their Paint Shop. This was achieved through the implementation of ambient temperature phosphate (at 38°C) developed by PPG Asian Paints in its Pretreatment Electrodeposition (PT-ED) line. This resulted in a significant reduction of carbon emissions of approximately 1800 tons per annum in the pretreatment process, compared to the conventional process, which typically operates at 42 ~ 50°C.

The ambient temperature phosphate technology provides several important benefits, such as considerable fuel savings by removing the need for heating and consequently lowering fuel consumption. This cutting-edge method also results in a significant drop in carbon emissions, with an estimated reduction of around 1800 tons each year. Additionally, the technology improves overall process efficiency by simplifying operations and minimizing maintenance requirements.

Commenting on the development, Biju Balendran, Deputy Managing Director, JSW MG Motor India said, “At JSW MG Motor India, sustainability isn’t just a corporate mandate; it’s embedded in our philosophy and drives our innovation. This new PT-ED line showcases that spirit of innovation, allowing us to enhance our green manufacturing process vision and set a new industry benchmark for sustainable practices. Through strong partnerships like the one with PPG Asian Paints, and our shared vision for a sustainable future, we’ve significantly reduced carbon emissions since 2022. We’re committed to continuing our work towards addressing environmental challenges.”

Jitendra Kalra, CEO, PPG Asian Paints said, “Our Partnership with MG underscores our commitment to sustainability and innovation. Through our joint efforts and shared expertise, we are taking a significant step forward in promoting energy conservation, and we are delighted to be a part of the brand’s sustainability initiative.”

In 2022, JSW MG Motor India was one of the world’s first automotive brands to adopt ULTRAX Degreaser, a liquid alkaline degreasing cleaner developed by PPG Asian Paints. This, along with the implementation of High Throw Low Cure Cathodic Electro Coating Paint, has already contributed to a substantial CO2 reduction of 787 tons/annum. Additionally, the company conserved energy & fuel through Low-Temperature Phosphate (VERSABOND) and High Throw Low Cure Cathodic Electro Coating Paint, leading to a CO2 reduction of 325 tons/annum and approximately 388 tons/annum, respectively. With all the above initiatives, overall, a 47% reduction in carbon emissions has been achieved.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

With this, Euler Motors customers can access fast chargers at important high-demand locations along their daily routes.

Euler Motors and Tata Power Renewables signed a long-term Memorandum of Understanding (MoU), under which Tata Power Renewables will provide Fast Chargers for Euler Motors’ entire product range to ensure seamless charging accessibility to all customers.

Euler Motors’ customers will receive Smart cards, allowing seamless and easy access to Tata Power Renewables charging stations.The MoU was signed in the presence of Virendra Goyal, Head Business Development – EV Business, Tata Power EV Charging Solutions Limited (TPEVCSL) and Ashish Tandon, Global Head – Customer Excellence, Euler Motors, marking a key milestone in advancing India’s EV ecosystem.

This partnership directly addresses one of the biggest needs for commercial EV users — charging accessibility. Unlike conventional fuel stations, EV charging requires strategic placement based on fleet duty cycles. Through this MoU, Tata Power Renewables will install, operate, and maintain fast chargers, ensuring high uptime and reliability, while Euler Motors will facilitate rent-free spaces for Tata Power’s chargers, reinforcing the mutual commitment to advancing India’s EV ecosystem.

Tata Power Renewables will also modify chargers, if necessary, to the higher capacity that is delivered by Euler Motors. Euler Motors’ HiLoadEV is the only 3W commercial EV in the segment with fast-charging capability, enabling a full charge in just 30 minutes to maximize uptime and efficiency.

Euler Motors is today the only commercial EV in both 3W and 4W segments to offer fast charging capabilities and this partnership builds on/ leverages the combined expertise of both companies to enhance fast charging infrastructure availability, reduce range anxiety, and encourage India’s transition to electric mobility.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Daimler India Commercial Vehicles (DICV) offset a total of 22,970 tons of CO2e by sourcing renewable power, underscoring its strong commitment to decarbonisation and sustainability.

DICV, a wholly owned subsidiary of Daimler Truck AG, utilised 100% renewable power at its state-of-the-art Oragadam production facility, ahead of its sustainability roadmap. This achievement underlines DICV’s commitment to environmental protection and marks an important step, as the company has successfully reduced its Scope 2 emissions ahead of the original end-2025 target.

From the outset, DICV has placed climate and environmental protection at the core of its operations, with a focus on reducing CO2e emissions and optimising energy consumption. Since 2018, the company has steadily expanded its renewable energy initiatives culminating in the implementation of cutting-edge infrastructure.

This achievement was due to DICV’s forward-thinking renewable energy strategy, which combines onsite solar power generation with offsite renewable power procurement. A total of 22,970 tons of CO₂e is offset through the sourcing of renewable power, underscoring DICV’s commitment to decarbonization.A key element of this strategy is a renewable power generation plant with a peak capacity of 4,300 kW, powered by 15,000 solar panels. This plant offsets approximately 4,000 tons of CO₂e emissions annually, contributing to 17% of the renewable in-house power generation.

Satyakam Arya, Managing Director & CEO, Daimler India Commercial Vehicles, said,

“We have made significant strides in positioning DICV as a leader in sustainable manufacturing and we are proud to achieve 100% renewable power utilization at our Oragadam facility. This milestone, achieved ahead of target, demonstrates our commitment to decarbonizing operations. Since 2018, we have focused on building the infrastructure to increase our reliance on renewable power and now we have reached 100% renewable power utilization under Scope 2 emissions. Supportive state and central policies, such as green power purchases through various energy sources available under the regulatory framework, played a vital role in this accomplishment.”

In addition to renewable power, DICV remains committed to energy efficiency and exploring alternative renewable sources to minimise CO2e emissions. These initiatives reflect the company’s dedication to creating a carbon-neutral future. By integrating advanced sustainability practices, DICV continues to set industry benchmarks, drive meaningful environmental impact, and shape a greener tomorrow.*”CO2e” refers to carbon dioxide-equivalent emissions, and includes not only CO2, but also other greenhouse gases. It is considered a more accurate measurement of global warming potential.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Zypp Electric aims to scale its fleet in the next 12-18 months, aligning with its goal of achieving 100% electrification by 2028. The new fleet will be deployed across India’s top eight cities, including Delhi NCR, Mumbai, Bengaluru, Hyderabad, Pune, Lucknow & Jaipur.

Zypp Electric, a tech-enabled EV-as-a-service platform, in partnership with Indofast Energy (A 50-50 joint venture between IndianOil and SUN Mobility), is expanding with a last-mile logistics plan. The company intends to deploy 100,000 electric two-wheelers (E2Ws) over the next 12-18 months. This landmark procurement builds upon the successful deployment of 10,000+ EVs by Zypp Electric with Indofast Energy’s battery-swapping infrastructure. With Indofast Energy’s extensive network, this expansion will ensure seamless operations and accelerate large-scale EV adoption across the target cities.

Zypp Electric has set a target of achieving 100% electrification by 2028, and this large-scale deployment is a step in that direction. The expanded fleet will help the company achieve a fivefold growth, scaling from 20,000 to 100,000 vehicles within the next 12 to 18 months and a further 500,000 vehicles in the following 36 to 48 months. This initiative will drive widespread EV adoption, ensuring seamless and sustainable last-mile logistics in India.

The new fleet of 100,000 E2Ws will be deployed across India’s top eight cities, including Delhi NCR, Mumbai, Bengaluru, Hyderabad, Pune, Lucknow & Jaipur enhancing efficiency for delivery partners and enterprises. With Indofast Energy’s cutting-edge battery-swapping network, riders gain unlimited range and near-zero downtime- a game changer in urban mobility. Its rapid 60-second battery swap eliminates long charging waits, keeping delivery partners and EV users on the move. In Delhi NCR and Bangalore, Indofast Energy has an extensive network of swap stations strategically placed every 1.5 km, ensuring seamless and hassle-free battery access. This dense coverage is a game-changer for delivery professionals, helping them maximize productivity and earnings while reducing operational stress.

As Zypp Electric and Indofast Energy gear up for this transformative phase, the companies remain steadfast in their combined vision of creating a cleaner, greener, and more efficient transportation ecosystem for the future.Speaking on the announcement, Tushar Mehta, Co-founder & COO at Zypp Electric, said: “At Zypp Electric, we are committed to redefining last-mile logistics with sustainable and cost-effective EV solutions. This major expansion will solidify our market leadership in India but also propel us towards global markets in Southeast Asia, the Gulf, and Africa.”

Rajat Malhan, Senior Vice President, of Indofast Energy said, “As we strengthen our groundbreaking partnership with Zypp Electric, we’re not just expanding our fleet – we’re revolutionizing the fabric of urban mobility. The deployment of 100,000 battery-swappable EVs is a resounding testament to our unwavering commitment to electrify India’s logistics landscape.”

With a growing footprint in India’s urban mobility ecosystem, Zypp Electric is now looking to extend its reach beyond domestic borders. This move aligns with the company’s long-term vision of becoming a global leader in EV fleet services, catering to emerging demand in international markets.”

Indofast Energy too has a vision to serve over a million EV users and is expected to scale up to 10,000 battery-swapping stations across 50+ cities within the next three years. This expansion will provide a robust alternative to traditional charging, eliminating concerns related to battery cost, maintenance, replacement, and charging time.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

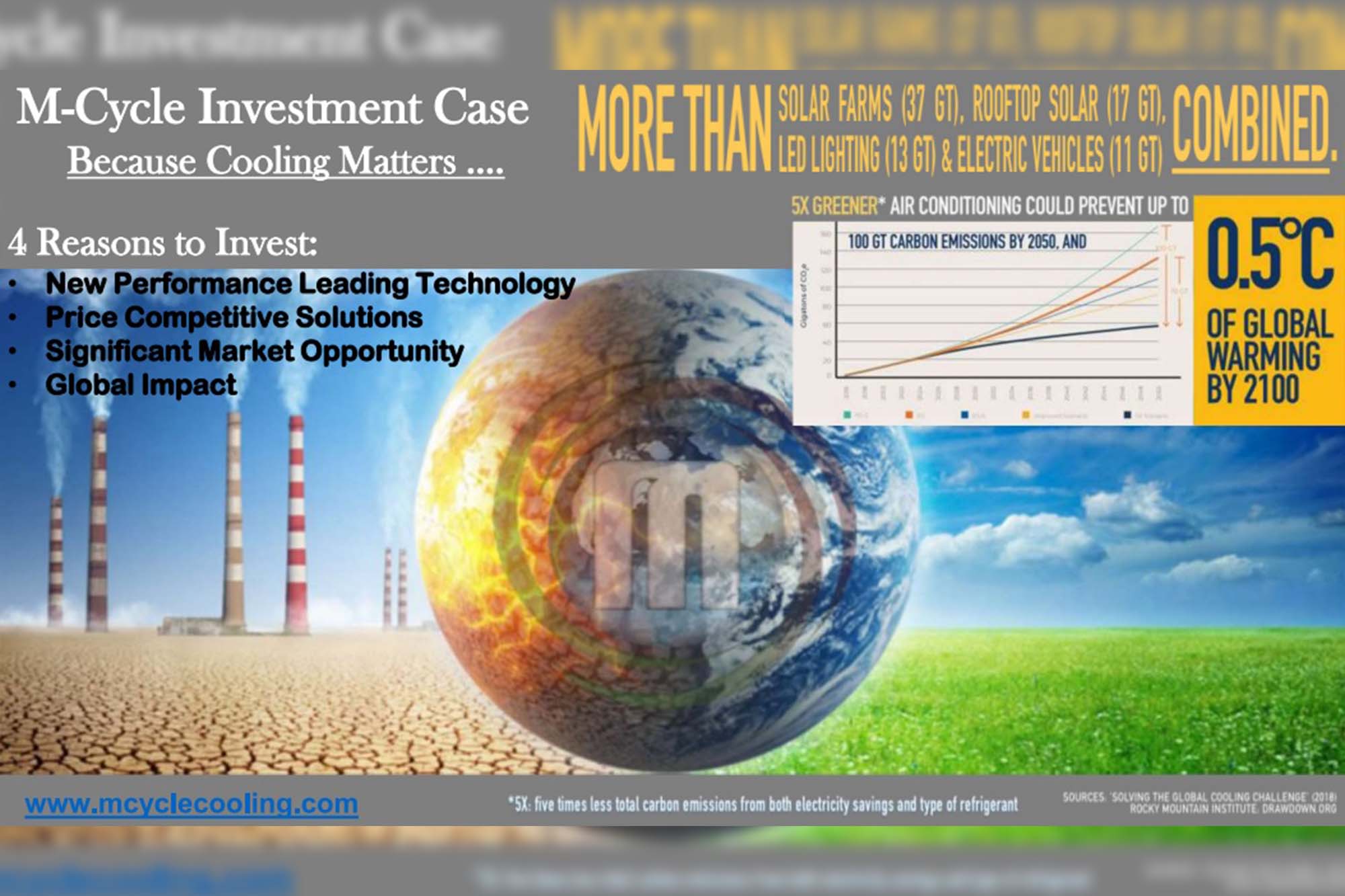

The Maisotsenko Cycle (M-Cycle) is a cooling technology that increases electric car cables’ capacity to 2000 A-10000 A, reducing charging times to less than 1 minute with suitable batteries and components. Alexey Polyakov, General Manager of Air To MC2—Maisotsenko Cycle Air Cooling, discusses methods to tackle slow charging due to inadequate cable cooling.

The adoption of electric vehicles faces a considerable challenge due to slow charging at charging stations caused by inadequate cable cooling. Current commercial charger capacity is restricted to 500 A due to thermal constraints. Technologies like liquid-cooled charging cable systems for fast EV charging can charge 500 Amperes in 15 minutes.

The Maisotsenko Cycle (M-Cycle) is a unique cooling technology that can cool electric car cables, increasing current capacity to 2000 A-10000 A. It is expected that EV charging times will be reduced to less than 1 minute with appropriate batteries and components. The M-Cycle uses evaporative cooling to cool and remove heat from charging cables. This allows for a higher current capacity than existing ultra-fast charging cables and improves the customer experience.

The M-Cycle has unique properties which cool any subject from its highest temperature (100°C, 500°C, or 1000°C) to the dew point temperature of the ambient air. The heat extracted from the electrical charging cable is not wasted but instead converted into additional cooling capacity for better efficiency. The M-Cycle cooling system excels at high temperatures and heat fluxes, making it ideal for cooling charging cables. It can handle heat levels beyond current technologies’ capabilities, demonstrating its unique ability to cool objects at extremely high temperatures and heat fluxes.

Electric vehicles are replacing traditional ones at a rapid pace. The world is thus focusing on high-power charging standards for medium- and heavy-duty vehicles, such as Megawatt Charging Systems (MCS). The Megawatt Charging System (MCS) is a high-power connector standard for charging large electric vehicles (EVs) like trucks, buses, and heavy-duty equipment. It can deliver up to 3.75 MW of charging power, reducing charging time for these vehicles. MCS is anticipated to contribute to electric commercial transportation, decrease fossil fuel usage, and promote sustainability in logistics and heavy industries.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Chicago Pneumatic offers reliable compressors to uplift EVs, with energy efficiency as a core.

Electric vehicles (EVs) are no longer a futuristic dream; they’re a present reality reshaping the automotive industry. India, a burgeoning EV hub, is riding this wave of transformation, driven by innovations in manufacturing and the urgent need for robust infrastructure. At the core of this revolution lies Chicago Pneumatic (CP), whose cutting-edge air compressors enable efficiency, precision, and sustainability across the EV ecosystem.

The changing landscape of EV manufacturing

changing landscape of EV manufacturing • Smarter production techniques – EV manufacturing is synonymous with hightech processes. From assembling battery packs to building electric motors, precision is non-negotiable. Chicago Pneumatic’s screw compressors power robotic arms and pneumatic tools on production lines, ensure seamless assembly and reduce downtime. This technological backbone guarantees that every EV component is built to exacting standards.

Lightweight innovations – EV efficiency hinges on weight reduction. Manufacturers are increasingly adopting aluminium and composite materials. Here, CP’s compressed air solutions shine—supporting processes like cutting, shaping, and assembling these materials with impeccable accuracy.

Clean battery production—Batteries are the beating heart of EVs, and their production demands a contaminationfree environment. The filtration system supplied by CP delivers pure, clean air, maintaining stringent quality standards while minimising risks to sensitive components.

Sustainability at the core: As the world prioritises greener practices, EV manufacturers follow stricter norms. CP’s energy-efficient compressors, especially its variable-speed models, cut energy consumption while reducing carbon footprints. This alignment with global sustainability goals makes them indispensable to the industry.

Building EV infrastructure: The role of CP

A robust infrastructure is the foundation of any successful EV ecosystem. Chicago Pneumatic’s air compressors play a vital role in key areas:

EV charging stations—Expanding charging networks is critical to overcoming range anxiety. CP’s compressors aid in constructing and maintaining charging stations, powering cooling systems and pneumatic controls for smooth operation.

Battery recycling plants – As EV adoption grows, so does the need for efficient battery recycling. CP’s air compressors drive processes like crushing, sorting, and material recovery, supporting a circular economy and reducing environmental impact.

Workshops and service centres—EV maintenance requires specialised pneumatic tools. CP compressors deliver reliable performance, enabling technicians to service EVs effectively and keep them on the road longer.

Supporting supply chains—Beyond EV production, CP’s compressors enhance warehouse automation and transportation equipment efficiency, ensuring the smooth functioning of the entire supply chain.

Addressing India-specific challenges

India presents unique hurdles for the EV industry, from extreme weather to energy constraints. Chicago Pneumatic is stepping up to the challenge:

Durable designs: CP compressors are built to perform in high temperatures, humidity, and dusty environments, ensuring performance reliability.

Energy optimisation: Variable-speed models maximise power efficiency, addressing India’s energy limitations.

Localised support: CP’s extensive service network across India ensures timely maintenance and minimal downtime.

Why CP compressors are game-changers:

Chicago Pneumatic’s solutions stand out for their sustainability and costeffectiveness:

Energy savings: Reduced energy consumption lowers operational costs while aligning with eco-friendly goals.

High reliability: High-quality components minimise repair needs, saving time and money.

Eco-friendly production: Air treatment systems, including air dryers and filters, eliminate contamination risks, ensuring clean, sustainable processes.

The future is bright—and electric

India’s EV industry is accelerating, spurred by government initiatives and technological advances. Chicago Pneumatic is powering this growth, enabling manufacturers to adopt cutting-edge techniques and helping build the infrastructure that will drive EV adoption.

By integrating efficiency, precision, and sustainability into its solutions, CP is shaping the future of electric mobility. Whether extending battery life, reducing emissions, or addressing range anxiety is required, CP’s air compressors are more than just tools—they’re catalysts for a cleaner, greener tomorrow.

The EV revolution is about creating an ecosystem that supports a sustainable future. Chicago Pneumatics air compressors are vital in this journey, enabling breakthroughs in manufacturing and infrastructure development. As India steers towards electric mobility, CP is at the helm, driving innovation, reliability, and sustainable development.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Ministry of Commerce and Industry is hosting the Bharat Mobility Global Expo 2025. The event highlights the Urban Mobility and Infrastructure Show, which focuses on sustainable urban transportation systems like drones and public transport, as well as the Battery Show, Construction Equipment Expo, Steel Pavilion, Tyre Show, and Cycle Show, which features innovations in new models and accessories.

The event features more than nine concurrent shows, a series of engaging conferences, and dedicated pavilions; all centred on the 16 focus areas that reflect the diverse opportunities in the mobility value chain.

Covering over 200,000 square meters, the expo welcomes over 1,500 exhibitors, over 500,000 enthusiastic visitors, and 5,000 global buyers, establishing itself as a significant global mobility platform.

At the Curtain Raiser event on November 6th, Union Minister of Commerce & Industry Shri Piyush Goyal commended the efforts of supporting ministries, industry bodies, and the Engineering Export Promotion Council (EEPC) for organising a global mobility event in India. The Minister also unveiled the event brochure and film, marking the commencement of preparations for this landmark event. Shri Jitin Prasada, Union Minister of State for Commerce and Industry, also graced the event.

The Bharat Mobility Global Expo 2025 will follow the lead of last year’s edition, heralding a new era of collaboration and innovation in the mobility sector. Inspired by the 7Cs mobility vision set by the Prime Minister of India, Shri Narendra Modi, the global expo will celebrate India’s growing role as a worldwide hub for mobility.

Vishal Bhatnagar, CEO & Managing Director of MVD Auto Components Pvt Ltd., remarks that India’s largest automotive show has been renamed Bharat Mobility Global Expo (BMGE) from this year onwards. This brings under the umbrella of the entire mobility value chain—from vehicles under automobiles to construction equipment to components to be held concurrently across three venues in the National Capital Region of Delhi. The theme of BMGE 2025 is shaping the future of mobility. The future of mobility is exciting and rapidly evolving. Innovation will continue to play a key role in shaping a safer, more sustainable, and connected transportation ecosystem. Innovation in mobility will reduce emissions for a better tomorrow, improve safety, increase accessibility, enhance the driving experience, and create new business models for vehicle manufacturers and the components industry. It also aims to reduce accidents for passengers, increase mobility, and reduce fatigue for drivers.

As a 100% Indian company supplying leading vehicle manufacturers and parts distributors across more than 30 countries worldwide, we take great pride in “Naya Bharat—Samarth Bharat,” he said. They at MVD Auto Components feel confident that the future is full of opportunities for component manufacturers like us—with new technologies, innovation, and synergies leading to the growth of the entire ecosystem.

The expo is a grand exhibition highlighting the latest advancements and breakthroughs in the mobility ecosystem. Specialised showcases include Auto Expo—The Motor Show, which showcases products and technologies concerning multiple powertrains, Auto Expo—The Components Show, and the Mobility Tech Pavilion, which spotlights connected and autonomous technologies and infotainment systems.

Other highlights include the Urban Mobility and Infrastructure Show, which focuses on sustainable urban transportation systems like drones and public transport, and the Battery Show, Construction Equipment Expo, Steel Pavilion, Tyre Show, and Cycle Show, which features new models and accessories innovations. The event delves into EV infrastructure and alternative fuel technologies, such as hydrogen, covering the entire spectrum of automotive and mobility advancements. Complementing this vast exhibition, over 20 conferences are bringing together global experts to discuss various aspects of the mobility value chain, providing a holistic knowledge-sharing platform.

Nitin Jirafe, Managing Director of Tata Cummins Pvt. Ltd. and Head of Engine Business at Cummins India, believes that the automotive sector in India is transforming, propelled by growing infrastructure, stringent environmental norms, and evolving customer demand for sustainable performance. With over six decades of commitment to India, Cummins is driving this change by championing sustainability and empowering the automotive sector to adapt to this evolving landscape.

He approaches this change through three key pillars: first, by enabling technological innovation and a diverse portfolio of advanced diesel, natural gas, hydrogen, and electric solutions, providing tailored choices to reduce emissions; and second, by shaping the future of mobility. Any transformation requires collective efforts and meaningful partnerships among stakeholders. OEMs, technology providers, fuel and infrastructure stakeholders, and regulators must come together to accelerate zero-emission transitions. Third, by leveraging IoT and Industry 4.0 technologies while maintaining uniform product standards across the plants, they bring their manufacturing excellence, integrating global expertise with local capabilities. He added that this approach supports the Make in India initiative while enabling global supply chains outside India.

The expo hosts over 34 prominent vehicle manufacturers unveiling new models and electric vehicles alongside displays of electric, hybrid, CNG, and biofuel-powered vehicles from international and domestic companies. Leading pure EV manufacturers such as Ather Energy, Ola Electric, Vayve Mobility, Eka Mobility, and Vietnam’s Vinfast are further driving the electric revolution. Around 800 auto component manufacturers and 1,000 brands from over 13 global markets are exhibiting their products, technologies, and services tailored to OEMs and the aftermarket. Dedicated country pavilions from Germany, the UK, South Korea, and Japan, along with participation from nations like the USA, Spain, UAE, China, Russia, Italy, Turkey, Singapore, and Belgium, are making the event a global platform for innovation, collaboration, and growth in the mobility ecosystem.

Union Minister of Commerce & Industry Shri Piyush Goyal, while addressing the curtain-raiser event for the Bharat Mobility Expo in New Delhi, said that the event reflects India’s vision story and unifies the entire mobility value chain under a single umbrella. He said that the Expo’s theme, ‘Beyond Boundaries: Co-Creating the Future of the Automotive Value Chain,’ aligns seamlessly with the nation’s vision for a connected and integrated world.

Rajesh Menon, DG of SIAM, says that they would be organising the 17th edition of Auto Expo—the Motor Show under the aegis of the Bharat Mobility Global Expo 2025 from 17th–22nd January 2025 at Bharat Mandapam, New Delhi, in partnership with ACMA and CII. The first edition of Auto Expo was held in 1986. 34 vehicle manufacturers have participated in the exhibition and are showcasing vehicle technologies with respect to multiple powertrains. A few OEMs have also set up experience zones in outdoor areas. SIAM has set up separate thematic pavilions on decarbonisation, circularity, electrification, and road safety at this expo.

The Bharat Mobility Global Expo 2025 is a Ministry of Commerce and Industry-led initiative coordinated by Engineering Export Promotion Council India (EEPC India) with the joint support of 11+ Apex Industry associations, namely SIAM, ACMA, ICEMA, AТМA, IESA, NASSCOM, ISA, MRAI, ITPO, Yashobhoomi, IEML, IBEF, CII, and Invest India, along with PwC India as the knowledge partner. This expanded event is being held in collaboration with 15 ministries, state governments, industry associations, and numerous industry leaders.

Future of Mobility

By 2030, people will want personalised transportation solutions, making journeys more integrated, intelligent, and linked. With more than 60% of the world’s population predicted to reside in urban areas, urbanisation will change our perspective on mobility. Changing urban mobility patterns among younger generations demonstrate an increasing preference for bicycling, walking, public transportation, and shared mobility services over automobile ownership.

The Indian automotive industry is experiencing profound transformations throughout its value chain. With advancements in new technologies, the sector is being reshaped by emerging business models and shifting consumer demands. Simultaneously, evolving government policies regarding emissions and incentives push companies toward cleaner, more efficient solutions. This dynamic landscape drives innovation, compelling manufacturers to adopt sustainable practices. As traditional approaches are challenged, the industry is focused on electric vehicles, smart manufacturing, and improving operational efficiency, creating a fertile ground for disruptions that will define the future of India’s automotive sector.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

With 50 more LNG trucks, the Blue Energy Motors’ total fleet will grow to more than 175, reinforcing India’s green freight movement.

Blue Energy Motors, green-energy LNG-powered heavy-duty truck manufacturer, has secured the second tender from Container Corporation of India (CONCOR) for 50 LNG trucks, further strengthening its commitment to sustainable logistics and green mobility.

This new order builds on Blue Energy Motors’ successful deployment of more than 125 LNG trucks for CONCOR. With this latest addition, the total fleet will expand to more than 175 LNG trucks, further accelerating the shift toward cleaner transportation solutions. Deliveries for the new batch of 50 trucks are set to commence by the end of March 2025.

Anirudh Bhuwalka, CEO, Blue Energy Motors, said, “We are proud to continue our partnership with CONCOR in driving the transition to cleaner and sustainable logistics. This expansion further strengthens our leadership in LNG trucking and reinforces our commitment to decarbonising India’s freight transportation sector. We remain focused on delivering innovative and reliable solutions that align with India’s net-zero ambitions.”

Blue Energy Motors is at the forefront of the alternative fuel revolution, offering cutting-edge LNG-powered trucks that significantly reduce carbon emissions by up to 40% while ensuring optimal performance and better efficiency. With this latest order, the company continues to expand its footprint in India’s sustainable commercial vehicle segment, playing a vital role in the country’s clean energy transition.

As Blue Energy Motors continues to push the envelope in providing clean energy solutions for the commercial vehicle sector, it is poised to make significant contributions to India’s environmental sustainability goals, particularly in the crucial area of long-haul transport decarbonisation.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Satya Intl secures licenses for automotive, tubular, inverter, UPS batteries and auto accessories for Asian and African countries.

Satya Intl, a leading global conglomerate in automotive and consumer products, has entered into a licensing agreement with DURACELL, a global brand for batteries & power products. Satya Intl’s focus has an extensive range of lead acid, tubular, inverter, and ups batteries for consumers under the Duracell Brand. Alongside the battery range, Satya Intl will launch a series of automotive power accessories such as battery chargers/maintainers and jump starters, offering consumers a complete solution for maintaining and enhancing their vehicles

“At Satya Intl, we are dedicated to providing innovative and high-quality products that meet the diverse needs of our global customers,” said Rakesh Sharma – Managing Director at Satya Intl. “Our licensing agreement with Duracell Inc., of USA marks a significant milestone in our journey to enhance the automotive & tubular batteries and automotive accessories market in Asia and Africa. We aim to bring unparalleled value, performance, and convenience to our customers. Notably, we have a strong presence in India, where the demand for high-quality automotive products and power accessories is rapidly growing.”Satya Intl has been granted the authority to manufacture, market, and distribute the products under the Duracell brand in various Asian countries such as Afghanistan, Australia, Bangladesh, Bhutan, Brunei, Cambodia, India, Indonesia, Laos, Malaysia, Maldives, Myanmar, Mongolia, Nepal, Pakistan, the Philippines, Singapore, Sri Lanka, Taiwan, Thailand, Timor-Leste, Vietnam, and New Zealand along with African countries such as Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, the Central African Republic, Congo, Equatorial Guinea, Ethiopia, Ghana, Guinea-Bissau, Iberia, Ivory Coast, Kenya, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Nigeria, Palestine, Rwanda, Senegal, Seychelles, Somalia, South Africa, Sudan, Tanzania, Togo, Tunisia, Uganda, Zambia, and Zimbabwe.

The new range of products will be officially launched in mid-February 2025 and available to customers through Satya Intl’s distribution channels starting April 2025. Satya Intl is confident that they will set a new standard in the industry, delivering outstanding value and satisfaction to their customers.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Bharat Mobility Global Expo 2025 saw the launch of 56 new products from 22 different brands at Bharat Mandapam, Pragati Maidan, New Delhi, and 5 launches at Yashobhoomi, Dwarka. These products showcased various advanced vehicles, cutting-edge mobility solutions, and the latest components, ranging from superbikes and cars to buses and even ambulances.

The second day of the Bharat Mobility Global Expo 2025 witnessed the launch of 56 new products from 22 different brands at Bharat Mandapam, Pragati Maidan, New Delhi, and 5 launches at Yashobhoomi, Dwarka. Various advanced vehicles, cutting-edge mobility solutions, and the latest components were showcased, ranging from superbikes and cars to buses and even ambulances.

On the second day at Bharat Mandapam, VinFast Auto India announced the launch of its first two electric vehicles for the Indian market, the all-electric premium SUVs, the VF 7 and VF 6.

BMW India launched the all-new MINI Cooper S John Cooper Works Pack at an ex-showroom price of ₹. 55,90,000 and the BMW X3 at an ex-showroom price of ₹. 75,80,000–Rs. 77,80,000. Additionally, BMW Motorrad India launched two new bikes in the Indian market, the new BMW S 1000 RR and the BMW R 1300 GS Adventure.

JSW MG Motor India showcased 9 advanced models, launching MG Majestor. The showcased products include hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), battery electric vehicles (BEVs), and internal combustion engines (ICEs). Highlights included the IM5 sedan, IM6 electric SUV, MG HS PHEV, and MG7 Trophy Edition, showcasing cutting-edge technology and sustainable mobility.

Eka Mobility showed India’s largest-ever variety of electric commercial vehicles, including over 11 various platforms for electric buses, trucks, and SCVs. We are launching the new EKA-Connect for the Indian market. Their bus portfolio included of EKA COACH, EKA 12M, EKA 9M, EKA LF (Low Floor), and EKA 9M. The EKA truck lineup includes the EKA 55T and EKA 7T electric trucks, as well as the EKA 3.5T, 2.5T, 1.5T, EKA 3W CARGO, EKA 6S, and EKA 3S SCVs.

BYD India launched the BYD SEALION 7 Pure Performance eSUV at the Bharat Mobility Global Expo 2025. Additionally, BYD India also showcased the BYD SEALION 6, the BYD Super Plug-in Hybrid EV with DM-i technology, and the stunning Yangwang U8.

JBM Electric Vehicles launched 4 all-new electric buses on the second day of the Auto Expo 2025, ranging from a luxury coach and a medical mobile unit to an electric tarmac coach, among others. Highlights of the launch were Galaxy, an electric luxury coach; Xpress, an intercity bus; e-MediLife, a low-floor electric medical mobile unit; and e-SkyLife, a 9-meter electric tarmac coach.

Montra Electric (TI Clean Mobility) launched ‘EVIATOR’ (e-SCV) and Super Cargo (e-3-wheeler) in the presence of the entire leadership team of the brand.

Hyundai Motor Company launched 2 concept models of advanced electric three-wheelers and micro four-wheelers on the second day. Along with exploring contributions to the last-mile mobility market in India together with TVS Motor Company Ltd. (TVS Motor).Pinnacle Industries launched its next-generation ambulance range at the Bharat Mobility Global Expo 2025. The new range includes three cutting-edge ambulance models: AD-Gen Ultra, AD-Gen Ambulance, and Neonatal Ambulance.

Numeros Motors launched its multipurpose and reliable e-scooter, ‘Diplos Max,’ at an introductory ex-showroom price (Bangalore) of ₹. 1,09,999, including the PM e-drive scheme. Alongside, the company unveiled another unique platform, which will be India’s first bike-scooter crossover.

India’s first solar electric car, ‘Eva,’ was launched by Vayve Mobility at an introductory price of ₹ 3.25 lakh (ex-showroom). The solar electric car will be available in three different options: 9 kilowatt-hour (Whr), 12 kWhr, and 18 kWhr, with prices ranging between ₹ 3.25 lakh (ex-showroom) and Rs 5.99 lakh (ex-showroom).

SML Isuzu launched the Hiroi.EV while presenting 4 other products, including the AASAI MX, Premium Hiroi Bus, ATS-125 Multi stretcher ambulance, and the Samrat XT Plus Tipper.

Cummins Group in India (“Cummins”) announced the launch of its next-generation HELM™ (Higher Efficiency, Lower emissions, Multiple fuels) engine platforms, with the high-performance L10 engine, along with an advanced Hydrogen Fuel Delivery System (FDS) with Type IV on-vehicle storage vessels and the innovative B6.7N natural gas engine.

Godawari Electric Motors Pvt. Ltd. unveiled new additions to its product portfolio at the Bharat Mobility Global Show 2025. The company unveiled the Eblu Feo Z and Eblu Feo DX and launched the Eblu Rozee ECO. The Eblu Rozee ECO is priced at INR 2,95,999/- (ex-showroom). To improve customer convenience, the company also announced the release of the EbluCare app. An innovative smartphone app called EbluCare has been designed to make managing electric vehicles (EVs) easier.

Sarla Aviation unveiled first-ever product and India’s first flying taxi, Shunya, on the second day.

Motovolt Mobility introduced a selection of electric automobiles. The range includes the Hyper One, India’s first digital pedal motorcycle, and the Hum NYC, a multi-utility speed pedelec designed for last-mile delivery needs. The adaptable M7 and its sporty form, the M7 Rally, appeal to both logistical and personal commuting, while the revolutionary CLIP, a portable e-bike conversion kit, allows smooth e-mobility for current bicycles.

Olectra GreenTech Limited unveiled a 12-meter Blade Battery Platform, a 9-meter City Bus, a 12-meter Coach Bus, and a Blade Battery Chassis. These products are underpinned by cutting-edge technology and inclusive design.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mahindra has opened a state-of-the-art manufacturing and battery assembly facility at its Chakan plant, a fully integrated ecosystem for producing electric Origin SUVs.

Mahindra unveiled its new dedicated state-of-the-art manufacturing and battery assembly facility at the Chakan plant, a fully integrated ecosystem dedicated to producing electric Origin SUVs.

Strategically located within the company’s 2.83 km² Chakan manufacturing hub—one of India’s largest green-field projects, a water-positive facility, and 100% reliant on renewable energy—the new plant for EV operations underscores Mahindra’s commitment to innovation and sustainable manufacturing. As announced earlier, Mahindra has allocated ₹ 4,500 crores out of the total ₹ 16,000 crores planned in the F22–F27 investment cycle, which includes powertrain development, two product top hats including software & tech, and manufacturing capacity.

Mahindra’s EV manufacturing hub is a highly automated, integrated ecosystem with over 1000 robots and multiple automated transfer systems. Alongside a strong focus on skill development and quality, the EV facility targets a 25% gender diversity ratio, reinforcing the plant’s inclusive and future-ready work culture. Driven by this foundation, Mahindra is now charged up to roll out next-generation electric Origin SUVs.

The next generation EV plant

A footprint of around 88,000 m² for the EV domain.

Utilises a fully automated press shop, an AI-driven body shop, and one of India’s most sophisticated robotic paint shops to optimise quality and efficiency.

Deploys over 500 robots and fully automated transfer systems in the body shop, all monitored via an IoT-based “Nerve Centre” for real-time process insights and end-to-end traceability.

Adopts Industry 4.0 tech, AMRs (Autonomous Mobile Robots), and AGVs for seamless material movement, underscoring Mahindra’s commitment to safety, speed, and reliability in sustainable manufacturing.

Cutting-edge battery assembly

Operates as one of the world’s most compact battery manufacturing lines, employing patented processes and lean module assembly.

This fully automated plant integrates world-class manufacturing processes developed and implemented indigenously to produce/store/transfer high-performance, long-lasting batteries using industry 4.0 tech.

Employs a patented pallet design for optimal insulation and geometric accuracy, plus hidden cell terminal welding for enhanced connectivity and robust performance.

Performs multi-layered end-of-line testing simulating real-world conditions, backed by IP67 ingress protection, real-time temperature monitoring, and automated anomaly isolation.

Implements a no-fault-forward strategy coupled with proprietary switching technology that underscores superior product quality and reliability.

Reinforces Mahindra’s pledge to deliver durability, safety, and peace of mind through best-in-class battery solutions tailored for electric mobility.

Mahindra has inaugurated a state-of-the-art manufacturing and battery assembly facility in Chakan, marking a significant step towards shaping the future of mobility. By combining localised battery assembly, high-end automation, and a dedication to innovation, Mahindra is reinforcing its commitment to “Make in India for the World” and contributing to India’s efforts to meet its COP26 targets for 2030.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Euler Motors is a major part of India’s EV landscape, which includes advanced liquid cooling, robust BTMS, predictive maintenance, and connected systems. Their reliable, long-lasting batteries are to ensure optimal performance in extreme conditions and promote sustainable mobility.

What advanced technologies does Euler Motors deploy to produce reliable battery systems?

Euler Motors was the first to introduce cutting-edge liquid cooling technology, for long-lasting battery life, setting a new standard in the Indian commercial EV market. This innovative system prevents lithium plating during charge and discharge processes, which can degrade the cell’s charge-holding capacity over time. This effect becomes more severe at higher temperatures, and by keeping the battery cool, our liquid cooling system mitigates this issue, resulting in longer battery life and better performance.

With the launch of our first four-wheeler, the Storm EV, we continue to push the boundaries of performance with our ArcReactor™ 200 technology. It provides optimal battery performance while extending battery life even in extreme weather conditions. It is supported by a Vapour Compression Engine that provides dedicated thermal management, maintaining ideal battery temperatures for maximum efficiency.

The Storm LongRange 200 EV’s 30kWh battery features a proprietary laser-welded design, ensuring reliability in extreme conditions, from Rajasthan’s heat to Kashmir’s cold. It is fully water- and dust-resistant (IP67 rating) and utilises vapour compression for efficient cooling, extending battery life even in temperatures ranging from -40°C to 70°C. Proactive measures have also been implemented to address the depth of discharge concerns by incorporating higher reserves (10-15%). Predictive maintenance capabilities enhance reliability by monitoring the battery’s discharge levels and preventing overuse. We are redefining reliability and performance and ensuring our customers can trust Storm EVs for years.

How do the liquid-cooled battery pack and BTMS contribute to the overall performance of your vehicles?

Our vehicles are meant to carry maximum payload, which results in higher currents. Our battery pack incorporates active liquid cooling during charge and discharge cycles, even in extreme conditions. This improves performance, extends battery life, and reduces total cost of ownership. Integrated sensors continuously monitor the battery’s temperature, activating a coolant circulation mechanism when temperatures exceed predefined thresholds. We ensure the longevity and performance of our battery systems this way.

The Battery Thermal Management System (BTMS) in the HiLoad EV and Storm EV provides efficiency even under heavy loads or high temperatures. With real-time temperature regulation and the ability to optimise performance through software updates, the 4th generation BTMS enhances vehicle longevity while reducing the need for hardware upgrades. It reduces the cost while keeping the performance consistent.

How has Euler Motors contributed to reducing the environmental impact of commercial vehicles in India?

Our core vision is for India’s transition to sustainable mobility. The HiLoad EV has already helped reduce over 15,000 tonnes of carbon emissions, equivalent to the positive impact of planting 5.2 lakh trees. With the Storm EV, we aim to expand this impact and offer a zero-emission alternative for intra- and intercity cargo transport.

For example, the Storm LongRange 200 EV provides a 200 km range, enabling intercity movement between nearby locations, typically serviced by diesel vehicles. By offering this practical alternative, we help reduce emissions and improve air quality in urban and semi-urban areas. The focus is making EV adoption a seamless transition for businesses, ultimately contributing to cleaner environments.

How have you addressed battery life, charging infrastructure, and vehicle performance in diverse Indian conditions?

Battery health is impacted by both temperature and daily depth of discharge. We maintain optimal performance, even during extreme and temperate mid-seasons when humidity increases. The BMS monitors battery health and temperature, alerting the Vehicle Control Unit (VCU) if thresholds are exceeded. The VCU recalibrates energy usage and oversees power flow, enhancing efficiency and user experience, especially in high heat.

We have enhanced our charging infrastructure through strategic partnerships supporting the electrification of logistics and commercial transport in India. We partnered with Fyn Mobility to develop charging infrastructure across the country. The Storm LongRange 200 EV supports CCS fast charging, delivering a 100 km range in just 15 minutes, while the Storm T1250 EV offers similar fast-charging capabilities for shorter trips. This helps to alleviate concerns around downtime, making businesses operate efficiently without disruptions.

How do Euler Motors’ connected systems and predictive maintenance features benefit your customers?

Our connected systems, available through the Shepherd platform, provide real-time insights into vehicle performance, including fleet tracking, battery health, and charging status. This allows fleet managers to make informed decisions that optimise operations and reduce downtime.

Predictive maintenance features ensure that potential issues are addressed before they escalate into problems, further enhancing vehicle uptime. Additionally, our Over-The-Air (OTA) updates continuously refine vehicle performance based on real-world data and customer feedback. Security is also a priority, with features like 24/7 CCTV monitoring and anti-theft immobilisation providing added layers of safety for both the vehicle and its cargo.

We aim to provide customers with the tools they need to manage their fleets more effectively, reducing costs and improving operational efficiency by integrating these connected systems.

What steps are you taking to extend battery warranties and develop long-lasting technology?

Long-term reliability is a key focus for us. We offer a standard battery performance warranty of 3 years or 80,000 kilometres. For the HiLoad EV, we guarantee a 10-year battery lifespan, with a battery module replacement in the 5th year to align with EMI periods.

We provide an extended warranty of 7 years or 2,00,000 km for the Storm EV, backed by rigorous testing protocols, including submersion and stress tests across different climates. Our modular battery design allows cell replacements after five years, extending battery life without replacing the entire unit. This process retains essential components like electronics, sensors, temperature controls, and the battery management system, reducing ownership costs and encouraging EV adoption.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Ministry of Commerce and Industry is hosting Bharat Mobility Global Expo 2025 from 17th to 22nd January 2025, across three venues in Delhi NCR: Bharat Mandapam, New Delhi, Yashobhoomi, Dwarka, New Delhi, and India Expo Centre and Mart, Greater Noida.

The event will feature more than nine concurrent shows, a series of engaging conferences, and dedicated pavilions, all centred around the 16 focus areas that reflect the diverse opportunities in the mobility value chain.

Covering a massive area of over 200,000 square meters, the expo will welcome more than 1,500 exhibitors, over 500,000 enthusiastic visitors, and 5,000 global buyers, establishing itself as a significant global mobility platform.

At the Curtain Raiser event on 6th of November, Union Minister of Commerce & Industry, Shri Piyush Goyal, commended the efforts of supporting ministries, industry bodies, and the Engineering Export Promotion Council (EEPC) for organising this global mobility event in India. The Minister also unveiled the event brochure and event film, marking the commencement of preparations for this landmark event. Shri Jitin Prasada, Union Minister of State for Commerce and Industry, also graced the event.

The Bharat Mobility Global Expo 2025 promises to be yet another landmark event, following the resounding success of last year’s edition, heralding a new era of collaboration and innovation in the mobility sector. Inspired by the 7Cs mobility vision set by the Prime Minister of India Shri Narendra Modi, the global expo celebrates India’s growing role as a global hub for mobility, showcasing success across the automotive and mobility value chain and cutting-edge technologies.The expo will showcase a grand exhibition highlighting the latest advancements and breakthroughs in the mobility ecosystem. Specialised showcases will include Auto Expo – The Motor Show showcasing products and technologies with respect to multiple powertrains, Auto Expo The Components Show, and the Mobility Tech Pavilion, which will spotlight connected and autonomous technologies and infotainment systems. Other highlights include the Urban Mobility and Infrastructure Show, focusing on sustainable urban transportation systems like drones and public transport, as well as the Battery Show, Construction Equipment Expo, Steel Pavilion, Tyre Show, and Cycle Show, featuring innovations in new models and accessories. The event will also delve into EV infrastructure and alternative fuel technologies, such as hydrogen, covering the entire spectrum of automotive and mobility advancements. Complementing this vast exhibition, over 20 conferences will bring together global experts to discuss various aspects of the mobility value chain, providing a holistic platform for knowledge sharing.

The expo will host over 34 prominent vehicle manufacturers unveiling new models and electric vehicles, alongside displays of electric, hybrid, CNG, and biofuel-powered vehicles from both international and domestic companies. Leading pure EV manufacturers such as Ather Energy, Ola Electric, Vayve Mobility, Eka Mobility, and Vietnam’s Vinfast will further drive the electric revolution. More than 800 auto component manufacturers and 1,000 brands from over 13 global markets are going to exhibit their products, technologies, and services tailored to OEMS and the aftermarket. Dedicated country pavilions from Germany, the UK, South Korea, and Japan, along with participation from nations like the USA, Spain, UAE, China, Russia, Italy, Turkey, Singapore, and Belgium, will make the event a global platform for innovation, collaboration, and growth in the mobility ecosystem.

Union Minister of Commerce & Industry, Shri Piyush Goyal while addressing the curtain raiser event for the Bharat Mobility Expo in New Delhi said that the event reflects the India vision story and unifies the entire mobility value chain under a single umbrella. The Expo’s theme, ‘Beyond Boundaries: Co-Creating the Future of the Automotive Value Chain,’ aligns seamlessly with the nation’s vision for a connected and integrated world, he said. He further emphasised on the government’s commitment to support the sector in its aim to become the pinnacle for mobility technology across the world and encouraged a faster transition to electric vehicles. India’s story is a compulsive investment story that leverages skill, vision, and ambition. Bharat Mobility Expo helps showcase India’s story in attracting investments and expanding trade and exports, he said. He urged the participants to invite international players to expand their businesses and leverage India’s growth story.

The Bharat Mobility Global Expo 2025 is a Ministry of Commerce and industry-led initiative and is being coordinated by Engineering Export Promotion Council India (EEPC India) with the joint support of 11+ Apex Industry associations namely SIAM, ACMA, ICEMA, AТМA, IESA, NASSCOM, ISA, MRAI, ITPO, Yashobhoomi, IEML, IBEF, CII, Invest India along with PwC India as the knowledge partner. This expanded event will be held in collaboration with 15 ministries, state governments, industry associations, and numerous industry leaders

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The company has increased headcount at its Chennai plant by 600 and added a third shift, aiming to put its Chennai-based manufacturing plant at full capacity with both lines at three shifts by 2026.

Japanese auto major Nissan’s plans to turn around its Indian operations remain intact, and it is looking to increase headcount in the country despite the turbulence it is facing globally, according to a senior company official.

Frank Torres, Nissan India Operations President, said, “The company, which has increased headcount at its Chennai plant by 600 to add a third shift, does not foresee steps to cut 9,000 jobs and 20 percent production globally having an impact on India as long as it remains competitive in the market. Nissan is betting big on India, and the plans (for India) remain intact despite this global turbulence.”

Nissan is strengthening its production, and this initiative was supported with the addition of almost 600 new employments in its manufacturing plant in Chennai. Nissan has grown one full new shift. The company plans to put its Chennai-based manufacturing plant at full capacity with both lines at three shifts by 2026.“This move is to help the production shifts. We are expanding production very soon with two new models…this is despite the global action, which involves restructuring. We don’t forecast that the impact will be in India because our plans remain untouched. Of course, the key point for us is to keep being competitive. Because, in the end, this is what is considered most important inside Nissan.” Earlier in July this year, Nissan India announced that it is looking to introduce five models over the next 30 months as it looks to turn around its operations in the fast-growing Indian car market. The company has set a target of tripling its domestic and export volumes to 100,000 each per annum by the end of FY26.

The third shift at the Chennai plant started some weeks ago, as the company targets full capacity utilisation of the manufacturing plant. Nissan is now refurbishing one to adapt to new technology, such as EVs, ahead of the planned launch of an electric SUV.

“Increasing headcount is part of our commitment. We have committed to the Tamil Nadu government to grow our headcount next year based on the new investments, and we are well supported by the Tamil Nadu government.” Moreover, he said, the Renault-Nissan alliance had committed to more than 2,000 employment creations not just in manufacturing but also in other areas like R&D as part of their $600 million investment plan announced in 2023.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

JK Tyre & Industries has introduced Off-the-Road (OTR) tires specifically designed for the mining sector at Bauma Conexpo 2024 India. The new offerings include 17.5-25 VEM 63 L5 for wheel loaders and 16.00-25 VEM 99D E3 for wide-body dump trucks.

Indium Corporation disclosed the global availability of CW-807RS, a new high-reliability, halide- and halogen-free flux-cored wire that improves wetting speeds and cycle times for electronics assembly and robot soldering applications.

CW-807RSis a no-clean formula designed to maximise the solderability of a halogen-free cored wire solder flux. It is an upgraded version of Indium Corporation’s CW-807 formula, which has been popular with electronics assemblers and other customers for many years. This new halogen-freeversion will provide improved wetting speeds and contains the company’s industry-leading spatter control technology.

Halogen-free CW-807RS delivers several benefits to users, including faster wetting speeds, Clear residues for electronics assemblers that use high (>385°C) tip temperatures and tend to experience charring and tip build-up and improve cycle times in robotic soldering applications.

Robert McKerrow, Product Manager for Flux-Cored Wire, Wave Solder Flux, and Bar Solder at Indium Corporation, said, “The improved wetting and spatter performance make CW-807RS an excellent no-clean, high-reliability flux-cored wire option for many of our customers, especially in robotic soldering applications. We’re excited to now offer this solution, combining cutting-edge innovation with proven technology to meet the needs of our customers.”

CW-807RS provides exceptional benefits in manual and robotic soldering applications requiring an “L” IPC classification and halogen-free wire, as well as in manual and robotic soldering applications requiring extra wetting power to achieve higher throughput while remaining halogen-free. Additionally, the spatter control technology within the flux produces an aesthetically pleasing board post-soldering by leaving minimal spattering and a clear to light-coloured residue.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The collaboration aims to contribute to India’s EV transition by delivering locally manufactured solutions. The partnership ensures that the chargers meet global standards while being tailored to the Indian market.

Delta Electronics India signed an MOU with ThunderPlus, a leading two-wheeler (2W) and three-wheeler (3W) electric vehicle (EV) charging solutions provider. Under the aforementioned agreement, Delta will provide advanced high-efficiency 4kW rectifier modules, made at its new large manufacturing site in Krishnagiri, Tamil Nadu, to support ThunderPlus’ fast chargers for the low voltage market, specifically designed for 2W and 3W EVs.

Niranjan Nayak, Managing Director, Delta Electronics India, said, “Delta’s corporate mission is ‘To provide innovative, clean, and energy-efficient solutions for a better tomorrow’. Hence, our collaboration with Thunder Plus underscores Delta’s goal to contribute to India’s EV transition by delivering cutting-edge, locally manufactured solutions. Our fast-growing R&D capabilities in Bengaluru and manufacturing in Krishnagiri have been instrumental to this milestone.”

Manjula Girish, Business Head – EV Charging Infrastructure, Delta Electronics India, “Our 4kW rectifiers are a testament to Delta’s commitment to innovation and sustainability. Engineered with high energy efficiency of up to 93% and manufactured at our state-of-the-art Krishnagiri facility, these rectifiers exemplify the synergy between cutting-edge technology and localized manufacturing. ThunderPlus’ decision to integrate our rectifiers into their EV chargers highlights the trust in Delta’s capability to deliver superior performance and value. This partnership is a significant step toward enabling robust and energy-efficient charging solutions for India’s growing EV ecosystem.” Rajeev YSR, CEO – Thunder Plus, highlighted, “This collaboration with Delta Electronics brings world-class technology to India’s low-voltage EV charging market. Our customizable chargers cater to the unique requirements of OEMs and end-users, ensuring efficient and seamless integration with their operations. Together, we are building the foundation for a robust and sustainable EV charging infrastructure in India.”

This endeavor brings together Delta’s technological expertise in power solutions and ThunderPlus’ market leadership in EV charging systems. The chargers, developed with Delta’s advanced 4kW rectifier modules featuring energy efficiency up to 93%, are customizable and designed to meet India’s diverse requirements, making them a game-changer for the local EV market.

India’s EV sector is witnessing unprecedented growth, with the adoption of 2W and 3W EVs driving much of the demand. This Make in India chargers are tailored to the low-voltage segment under this partnership we aim to reduce charging downtime, alleviate range anxiety, and boost the productivity of EV users.

Thunder Plus, a leading provider of EV charging solutions in India, has already on boarded OEMs in the 2W and 3W segments. These chargers are equipped with advanced co-branding opportunities, reflecting the synergy between both organizations. The partnership ensures that the chargers are developed to meet global standards while being tailored to the Indian market.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

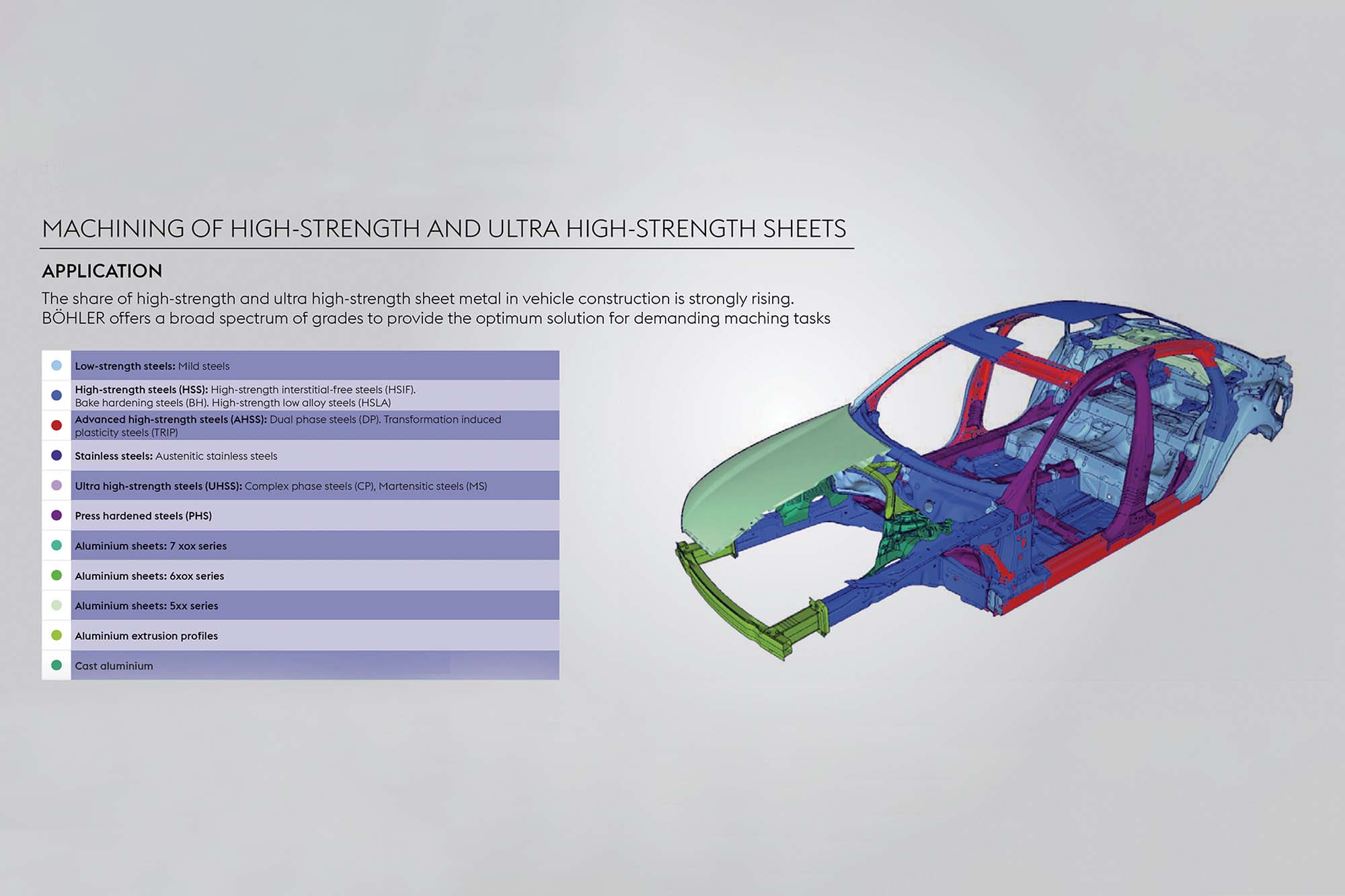

The automotive industry’s growth is powered by consumer demand, technological progress, and government support. Projections indicate market expansion in the coming years, with the industry expected to become the third-largest in the world by 2026. The focus would be on enhancing vehicle safety and performance. The development area is high-tensile strength sheets in the forming segment, offering superior safety and impact resistance.

High-tensile strength sheets have exceptional strength and durability, which is essential in automotive manufacturing. These sheets are designed to absorb and distribute impact energy during accidents, significantly improving passenger safety. The industry’s emphasis on lightweight yet robust materials makes high-tensile strength sheets an ideal choice.

High-tensile strength sheets prove excellent in various automotive applications, including body panels, chassis, and structural components. They offer enhanced strength-to-weight ratios, corrosion resistance, and fatigue durability for long-term reliability and safety. Manufacturers are adopting these materials to meet stringent safety standards and consumer expectations.

Trends and future requirements

The demand for high-tensile strength sheets is expected to rise as the automotive industry continues to innovate and prioritise safety. Future trends include higher-strength materials, improved formability, and advanced manufacturing techniques to produce complex shapes and components. Innovations such as hot stamping, where sheets are heated to high temperatures and then rapidly cooled in a die, are becoming more prevalent. This process increases the material’s strength and allows for the creation of intricate geometries.

Innovations in high-tensile strength sheet manufacturing and application

Advancements such as hot stamping and roll forming have efficiently produced high-tensile strength sheets with superior properties. Innovations in material science, including alloying elements and heat treatments, have further enhanced the performance of these sheets.

- Hot Stamping: This process involves heating steel sheets to over 900°C before forming and quenching them in a die. The rapid cooling results in ultra-high-strength, making it ideal for a car’s A-pillars, B-pillars, and side door beams.

- Roll Forming: This continuous bending operation forms high-tensile strength sheets into desired shapes with high precision and minimal waste. It’s useful for long parts with uniform cross-sections, such as side impact beams.

Safety regulations in the automotive industry

Safety regulations in the automotive industry are becoming increasingly stringent. New norms enhance vehicle safety and reduce fatalities. These regulations mandate advanced materials and technologies to improve crashworthiness and protect passengers.

- Bharat New Vehicle Safety Assessment Program (BNVSAP): This program sets stringent crash test standards for vehicles sold in India. It includes frontal and side-impact tests, pedestrian protection, and child occupant protection. The Ministry of Road Transport and Highways is also working on several other safety regulations, such as introducing driver drowsiness detection systems, blind-spot detection systems, and lane departure warning systems.

- Bharat New Car Assessment Programme (Bharat NCAP): India is introducing its vehicle safety standards called the Bharat NCAP. This program will assign star ratings to vehicles based on their safety and sturdiness, similar to the Global NCAP and European NCAP programs. This initiative will enhance road and vehicle safety by encouraging manufacturers to incorporate advanced safety features.

Pedestrian Protection Regulations: These regulations require automakers to design vehicles that minimise pedestrian injury in the event of a collision. High-tensile strength sheets help achieve this by deforming in a controlled manner to absorb impact energy.

High-tensile strength sheets are crucial for meeting these safety requirements. Traditionally, automotive companies used sheets with tensile strengths of around 600 MPa, usually made from High-Strength Low-Alloy (HSLA) steels. However, there has been a shift towards Partial Martensitic steels with tensile strengths ranging from 1000 to 1200 MPa. This change is driven by the need for materials that provide better impact resistance and safety during accidents. These high-tensile strength sheets are used for critical structural components such as A-pillars, B-pillars, and side door beams. Their ability to absorb and distribute impact energy makes vehicles safer for occupants and pedestrians.

Impact on the tooling industry

The shift towards high-tensile strength sheets necessitates changes in tool and die manufacturing. Conventional steels like D2 or 1.2379 are often inadequate for forming high-tensile strength sheets, leading to increased wear and reduced tool life. To address these challenges, the industry is moving towards powder metallurgical (PM) steels, which offer superior performance and durability.

Upgrading to PM steels provides better wear resistance, toughness, and thermal stability, enabling longer tool life and reduced maintenance. This transition enhances production efficiency and ensures consistent quality of formed parts.

Comparison between Conventional and PM Steels

When used with high-tensile strength sheets, conventional tool steels like D2 or 1.2379 are prone to wear and deformation, leading to frequent tool changes and downtime. In contrast, PM steels offer enhanced properties that are ideal for high-stress applications. They exhibit higher hardness, improved wear resistance, and better fatigue performance, making them suitable for the demanding conditions of automotive forming processes.

Benefits of using PM Steels

Using ESR/PM steels for tooling and dies offers several benefits, including:

- Increased tool life and reduced maintenance costs

- Enhanced precision and consistency in part production

- Improved overall productivity and efficiency

- Better quality of formed components, leading to improved vehicle safety and performance.

Conclusion

The automotive industry’s commitment to safety and performance drives the increased use of high-tensile strength sheets in the forming segment. These materials offer superior strength and impact resistance, aligning with the industry’s stringent safety regulations and evolving requirements. As manufacturers transition to high-tensile strength sheets, the need for advanced tool and die solutions becomes paramount. PM steels are crucial in meeting these demands, ensuring efficient production and high-quality components.

BOHLER provides advanced ESR/PM steels, such as BOHLER K340 ISODUR, K390PM, K490PM, and S390PM, for high-tensile strength sheets in automotive applications.

Cookie Consent MotoTech India

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Tesla unveiled its long-awaited robotaxi at a Burbank, California, event. Production is expected to begin in 2026 and cost less than $30,000.

At an event in Burbank, California, Tesla CEO Elon Musk disclosed prototypes of the Cybercab, the company’s new robotaxi. Production is expected to begin in 2026, with the vehicle expected to cost less than $30,000. Musk arrived on stage in one of the prototypes, showcasing its futuristic design and predicting a shift in focus from low-priced mass-market cars to robotic vehicles. He also announced an autonomous van called Robovan that can carry up to 20 people and goods but did not reveal its price or production schedule.

Robotaxis, a technology developed by Elon Musk, could take years to establish due to safety and reliability issues. However, Musk claimed that autonomous cars could be 10 times safer than humans and drive five to 10 times longer. People can regain their time with autonomy despite challenges like inclement weather, complex intersections, and pedestrian behaviour.

Cybercab/Robotaxi

Tesla’s self-driving Cybercab will be priced under $30,000, which is lower than the current Model 3 Sedan’s starting price of $42,000. However, Tesla’s history of overpromising and underdelivering on vehicle pricing, such as the Cybertruck, raises questions about whether the Cybercab will meet its anticipated price, as potential buyers remain cautious based on past experiences with the company.

The Cybercab robotaxi, with gull-wing doors and limited seating for two, uses cameras and artificial intelligence for navigation. It avoids common competitor hardware and charging ports and uses inductive charging for convenience.

In addition to the Cybercab, Tesla revealed a Robovan concept, a larger autonomous vehicle capable of transporting up to 20 people. Both vehicles signal Tesla’s expansion into the market, with the Cybercab being a more affordable option for consumers seeking self-driving cars through the Tesla network.

The company also plans to create a fleet of self-driving Tesla taxis, which can be hailed via an app, and Tesla owners can list their vehicles as part-time taxis. According to reports, the Robotaxi model is a futuristic two-seater with butterfly doors. It targets established autonomous taxi services like Waymo and Cruise.

Advancements in the automotive industry also elevate Indians since it is a wide domain for manufacturers. Piyush Yenorkar from L’ATELIER24 shares, “As exciting as these developments are global, I’m keen to see how India will embrace this technology. Tesla has expressed interest in entering the Indian market, but the big question is—will Nitin Gadkari give the green light for Tesla’s operations here? India’s push towards electric vehicles could be a game-changer for the country’s auto industry, but we still await official decisions.” Many other news viewers share the same concerns. However, India is unlikely to have the same early adoption levels as the US, Europe and China for driverless vehicles due to the lack of infrastructure.

India has a large workforce in the taxi and logistics industries. This could lead to economic consequences, including the necessity for workforce retraining in the transportation sector. Bringing this technology to a country like India, with a population of 1.4 billion and a large workforce reliant on driving jobs, the stakes are high. Amit Singh from Wepsol shares, “Even if Tesla’s vision materialises in the West, countries like India may face greater economic and social impacts. Is the workforce ready for such a shift, or will this exacerbate unemployment?”

Challenges

Tesla’s ambitious vision for autonomous transport faces challenges, including safety, which is crucial for full autonomy. Despite AI and sensor technology advancements, concerns persist about the system’s ability to handle “edge cases.” Consistently making safe decisions is important for gaining regulatory approval and public trust, as autonomous vehicles must consistently navigate these unpredictable situations.